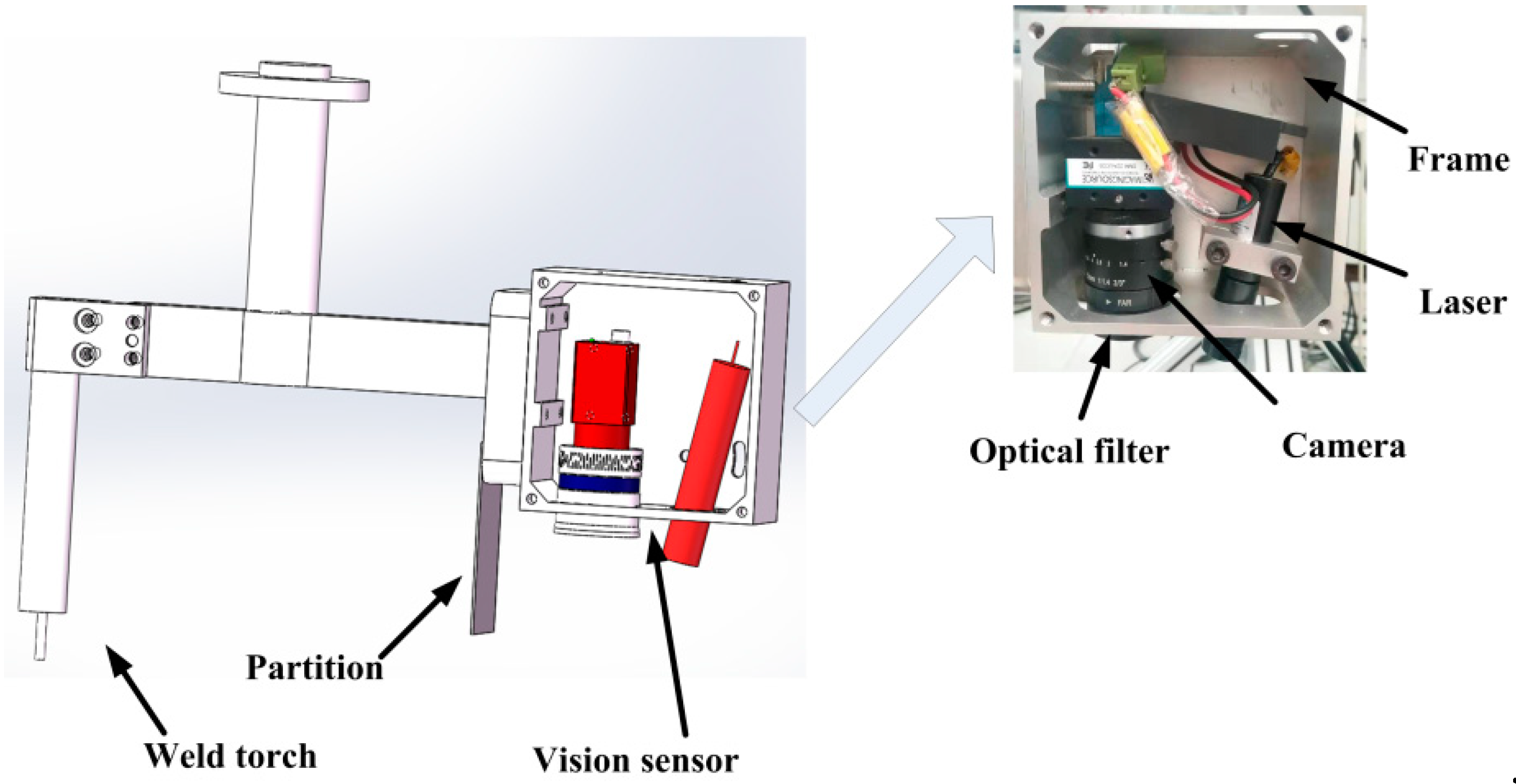

Our laser seam tracking system mainly consist of laser sensor and control host laser sensor is used for welding seam active acquisition control host is used for welding seam real time processing meanwhile keep real time communication with industrial robot or welding machine.

Laser seam tracking sensor.

The optical sensors for seam tracking support automated welding processes both with arc and laser.

Th6x seam tracking sensor the in process optical seam tracking with th6x paves the way towards a perfect welding seam.

Active seam detection scans the edge offset at the joint without contact using light bars thus ensuring precise positioning of the tool at all times.

All scansonic sensors are designed for applications in harsh industrial environments for example in welding cells and impress with their exceptional robustness.

So with laser seam tracking the sensor knows the distance between the laser emitter and the sensor on the camera allowing it to triangulate the position of that material it bounced off.

In a recent project for a nuclear vessel circumferential welder meta integrated control of the dls and weld head slides with control of the lincoln powerwave welding equipment.

Our laser seam tracking system mainly consist of laser sensor and control host laser sensor is used for welding seam active acquisition control host is used for welding seam real time processing meanwhile keep real time communication with industrial robot or welding machine.

Laser seam tracking systems for welding automation india s first and only laser sensor company kml sensors designs and manufacture laser vision systems for wide range of welding and 3d inspection applications.

This welding seam tracking system also has the locatin.

Laser seam tracking seam tracking also known as joint tracking involves real time tracking just ahead of where the weld is being deposited.

This allows for not only robot or machine trajectory shifts but also adaptive control such as adjustments to voltage wire feed or travel speed to change weld bead formation.

Our laser sensors are desinged and made in india for the world.

See th6x smartray 3d weld inspection.

Components and seams are recorded using a combination of laser lines and optical cameras allowing the course of the welding seam to be corrected in real time no matter the height or material.

The th6x seam tracking sensor uses a unique combination of laser lines cmos camera processor and laser triangulation principles to tracking the welding seam in real time and guide arc for a quality weld every time.